- Jobs

- Blog

-

Our Companies

- DVS TECHNOLOGY GROUP

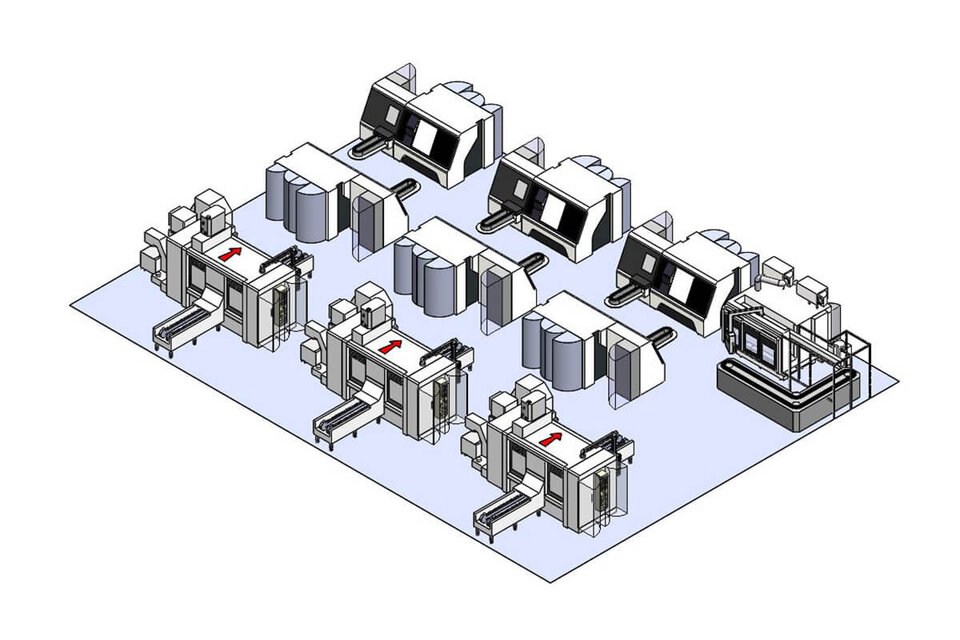

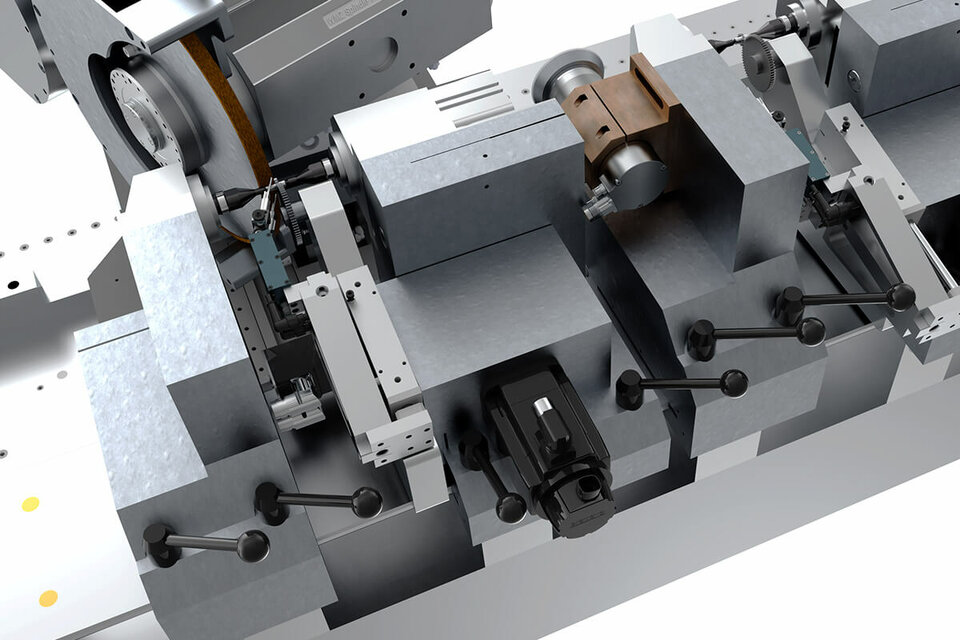

- DVS Machine Tools & Automation

- BUDERUS Schleiftechnik

- DISKUS WERKE Schleiftechnik

- DVS Universal Grinding

- Pittler T&S

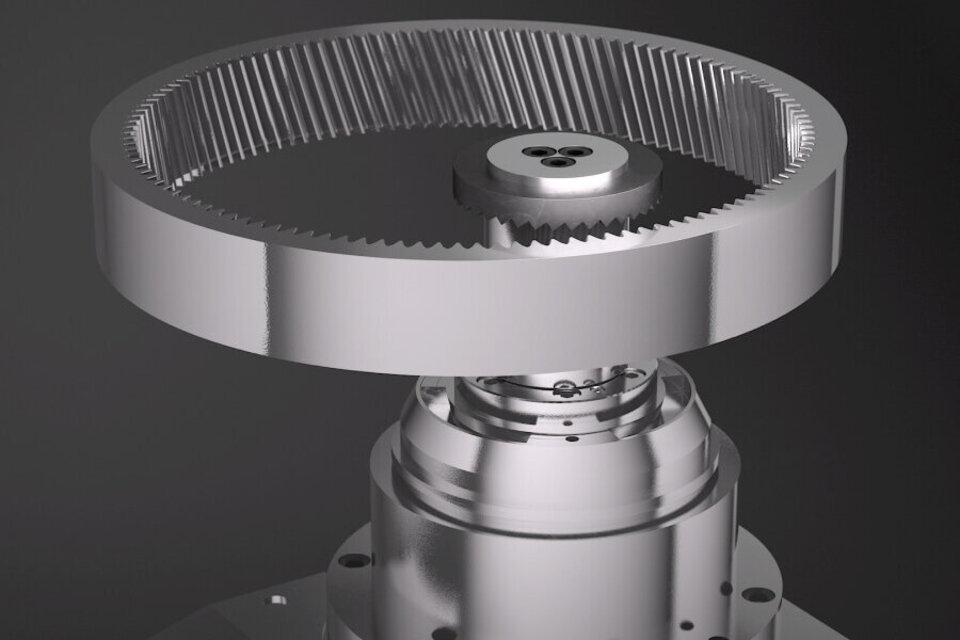

- Präwema Antriebstechnik

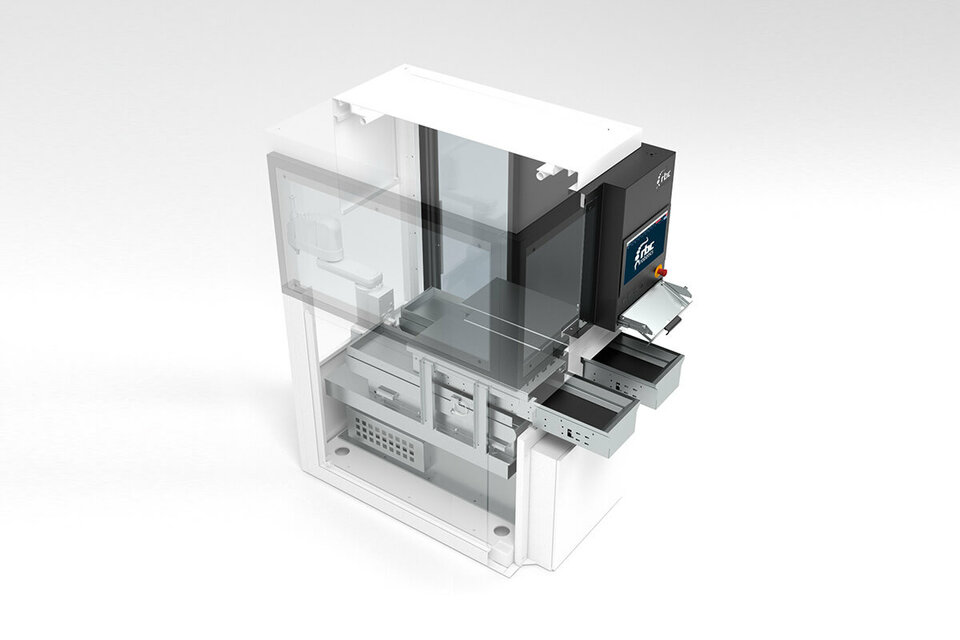

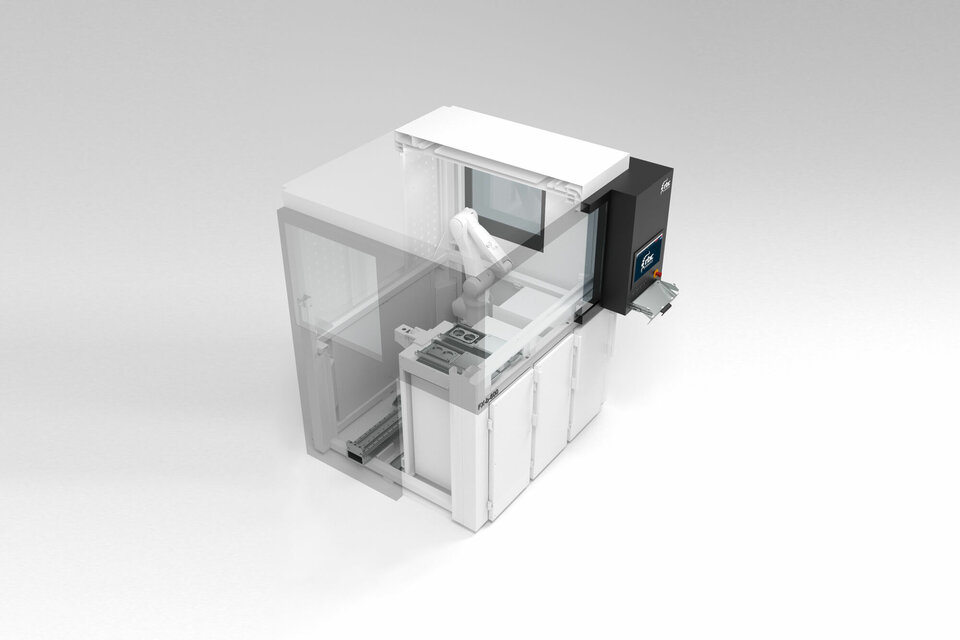

- rbc robotics

- DVS Service

- DVS Tools & Components

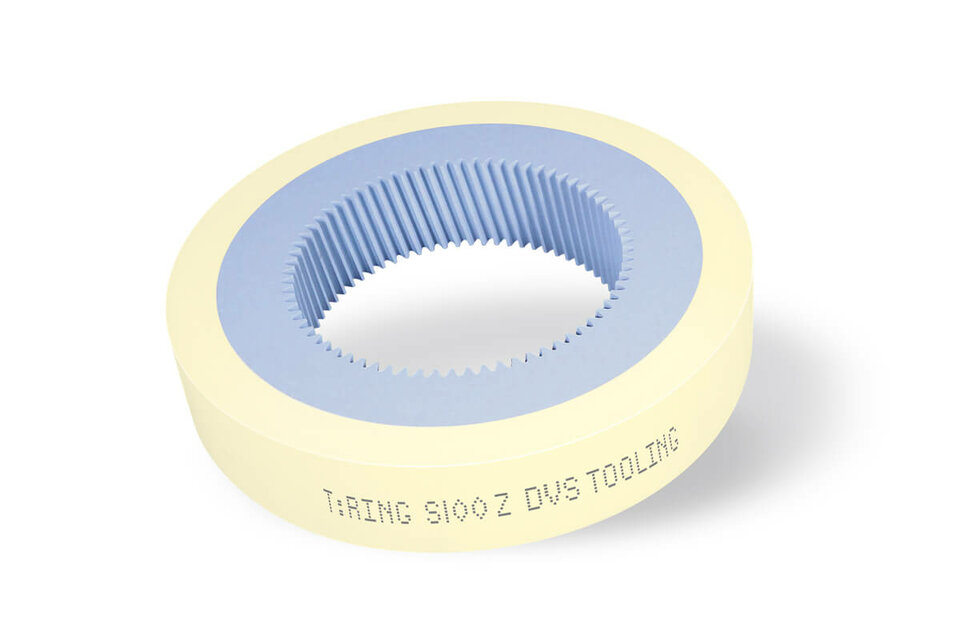

- DVS Tooling

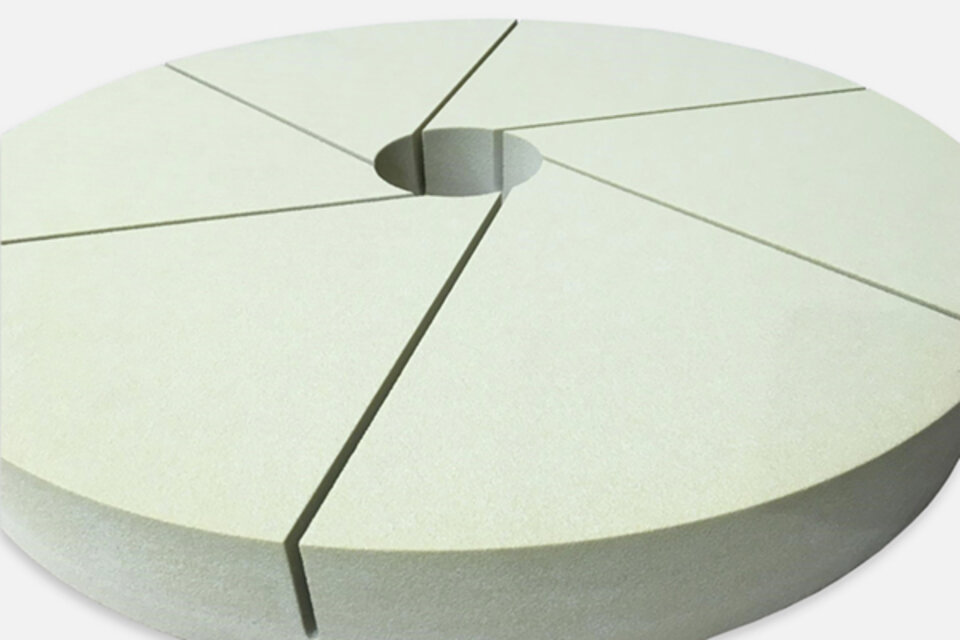

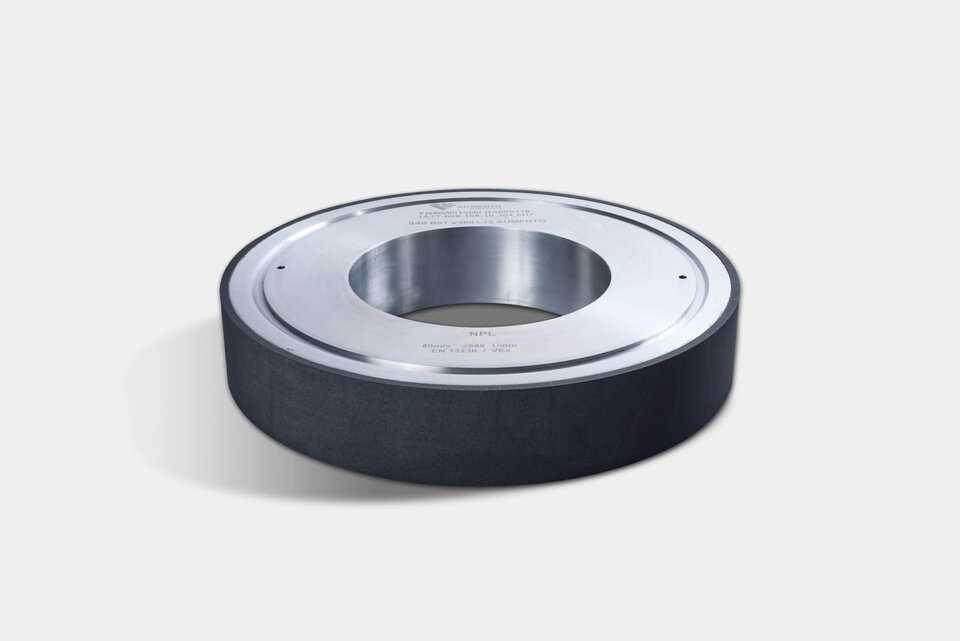

- NAXOS-DISKUS Schleifmittelwerke

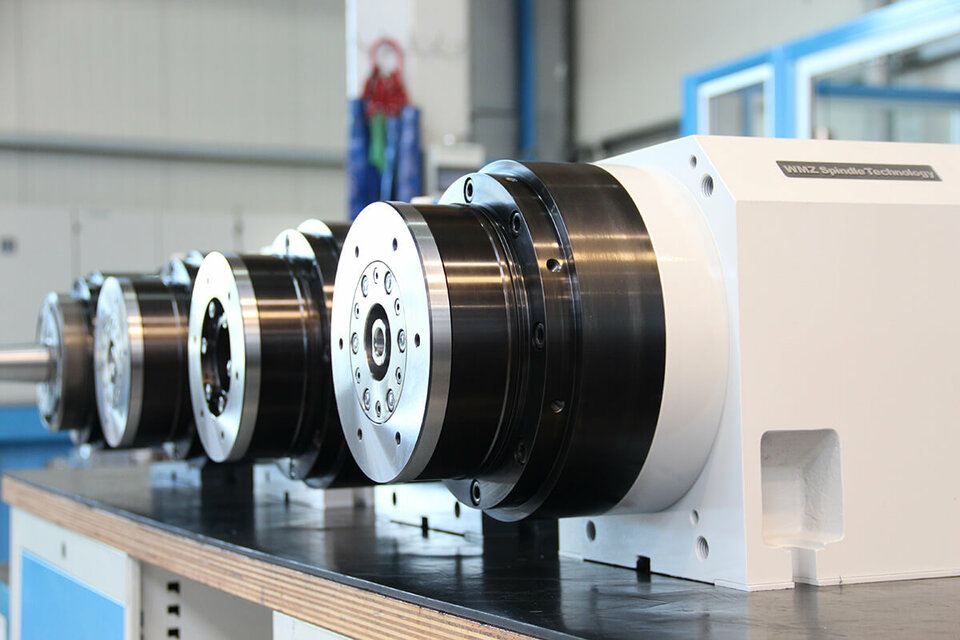

- WMZ Motorspindeln

- DVS Production

- DVS Production

- DVS Production South

- DVS Digitalisierung & Solutions

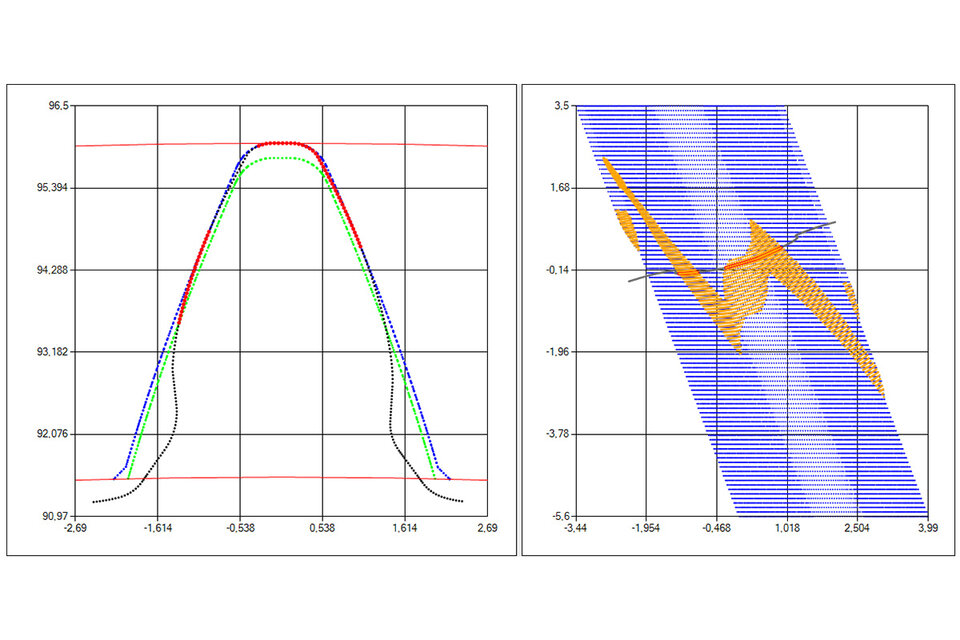

- DVS Digital

- EN

dvs-now.com ›

Post