When manufacturers or even suppliers plan the acquisition of a machine or entire plant today, they are usually faced with a major challenge.

On the one hand, there is growing pressure to achieve cost-effectiveness in the form of the lowest possible unit costs and new, more stringent quality requirements. On the other hand, the plant must be flexibly adaptable and convertible as quickly as possible with regard to the use of various technologies. And this during the procurement process, as well as later during the useful life of the machine.

This means that investment decisions are made at shorter notice, process designs are defined later and workpieces are varied much more frequently.

Machines must therefore deliver the highest quality at the lowest unit costs and also be easily and quickly adaptable to new requirements.

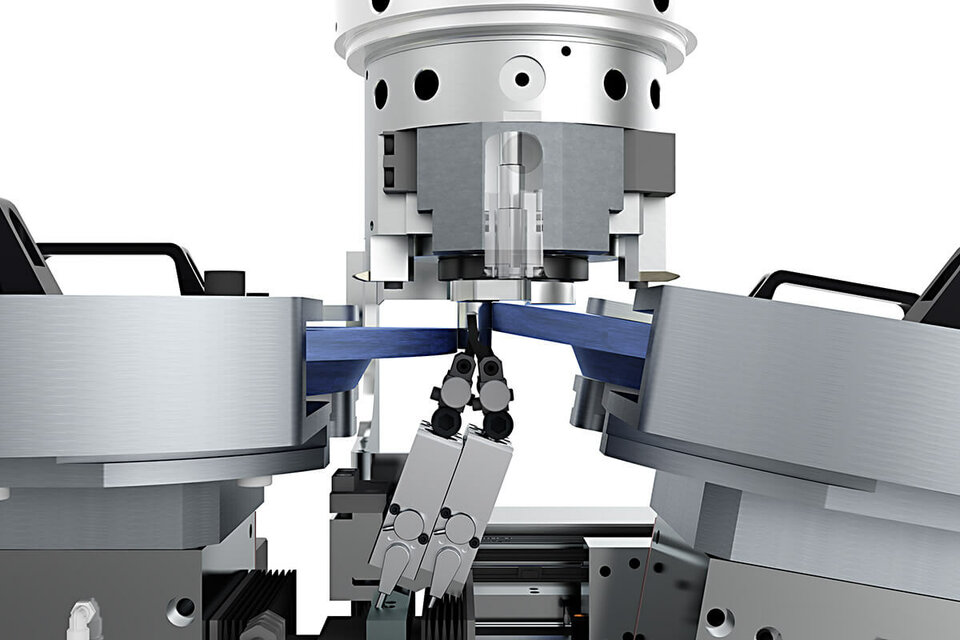

To meet these requirements, Buderus Schleiftechnik GmbH has now developed an innovative machine platform for precision machining of rotationally symmetrical, disk-shaped components up to D=220mm: the iCompact.

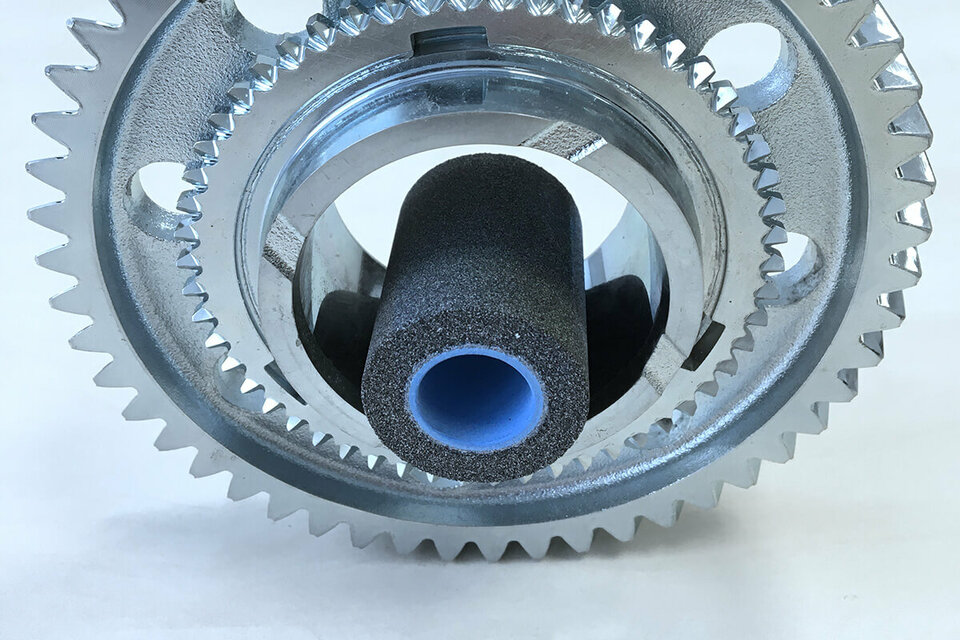

Both combination processes and simultaneous processes are possible on this system. Thanks to the flexible configuration options for a wide variety of processes, such as internal and external grinding, turning and honing, right through to the use of driven tools, the shortest possible cycle times can be achieved on the iCompact while maintaining the highest quality.

The machine is characterized by an extremely rigid machine structure made of natural granite, which contributes greatly to outstanding process reliability due to its thermal stability and vibration-damping properties.

The compact design of the iCompact enables a proven maximum of modularity. This creates a freely configurable workspace with optimum access options for maintenance and changeover work.

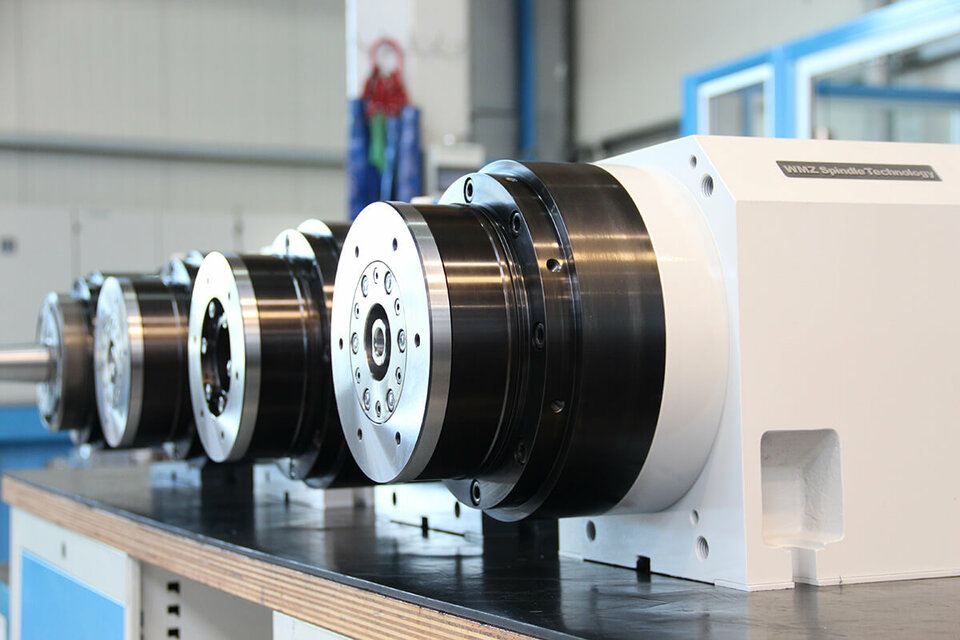

Proven DVS interfaces also lead to minimal changeover times. The fully integrated coolant system and the pioneering automation concept allow a footprint of just 11.5 m2 without the need for additional peripheral equipment. Flexibility and economy therefore pay off. And in terms of sustainability, the iCompact impresses with its positive energy and CO2 balances.

Such an innovative and sustainable machine concept is possible due to the close and interdisciplinary cooperation within the DVS Technology Group. Buderus Schleiftechnik GmbH benefits from know-how transfer and synergy effects between the partner companies during development and uses - and ultimately offers customers - technology expertise from a single source.