New center drive machine 235VM

At EMO 2023 as well as Motion+Power 2023 Buderus Schleiftechnik, a subsidiary of the DVS TECHNOLOGY GROUP, will be presenting a new hard-fine machining center from the 235V series: the 235VM, which is primarily designed for electric drive manufacturers. Applications include shaft-shaped components with high shape and position requirements and low tolerance specifications, such as rotor, input, intermediate, and drive shafts for electric drives.

The mixed design with a horizontally arranged workpiece spindle and vertically operating grinding spindles enables technological processes such as internal, external, plane, and bevel grinding, hard lathing, drilling, grating, honing, and milling. The solid structure with several compound slides allows components to be machined simultaneously inside and outside with up to four channels. In this way, the main time is significantly reduced and machining yields the highest quality standards in one clamping.

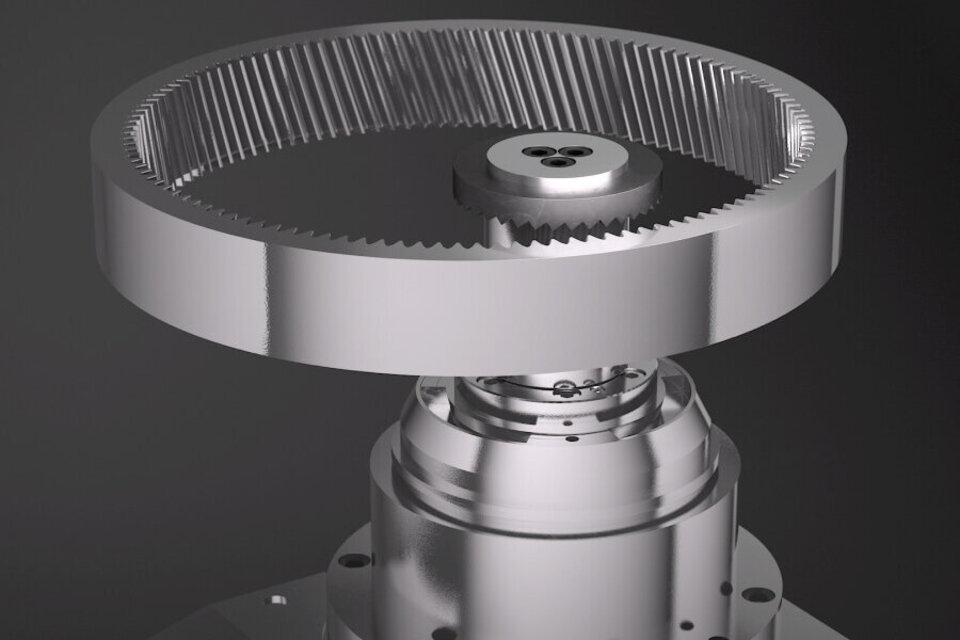

At the heart of the machine is the new Buderus center drive. With the narrow width of 100 mm, even the smallest shafts with a short clamping length can be processed simultaneously. The center drive reaches a maximum of 3,500 rpm, which enables hard turning processes. This enables combined processing of components with the highest quality. For milling operations, the center drive comes standard with an integrated sensor system, which makes it a fully fledged C-axis and allows positioning tasks in a range of ±3 angular seconds.

The 235VM is equipped with a natural granite bed, which has a low expansion coefficient for thermal stability and dampens vibration. The upper two of the four compound slides lie flat on the bed and can be fitted with multifunction heads. These can be fitted with various internal and external spindles, turning tools, and measuring probes.

In the lower part of the machine there is also a guide level with room for up to two compound slides. These can be equipped with grinding spindles and optional driven revolvers for simultaneous machining.

This means that besides high precision and short cycle times, the machine also offers a great deal of flexibility.

Altogether, the 235V line primarily allows complete finish machining of rotationally symmetrical shaft-shaped workpieces. After testing, however, other types of workpieces are also possible. Through consistent use of the modular principle, the machine can be custom tailored to the application or range of components.

When it comes to the hard-finishing of rotationally symmetrical components, BUDERUS Schleiftechnik is one of the leading providers of precision machinery for internal/external cylindrical and thread grinding, often in combination with hard turning. Find out more about the machine portpholio from BUDERUS Schleiftechnik.