In a word, Frank Götz

Our interview partner

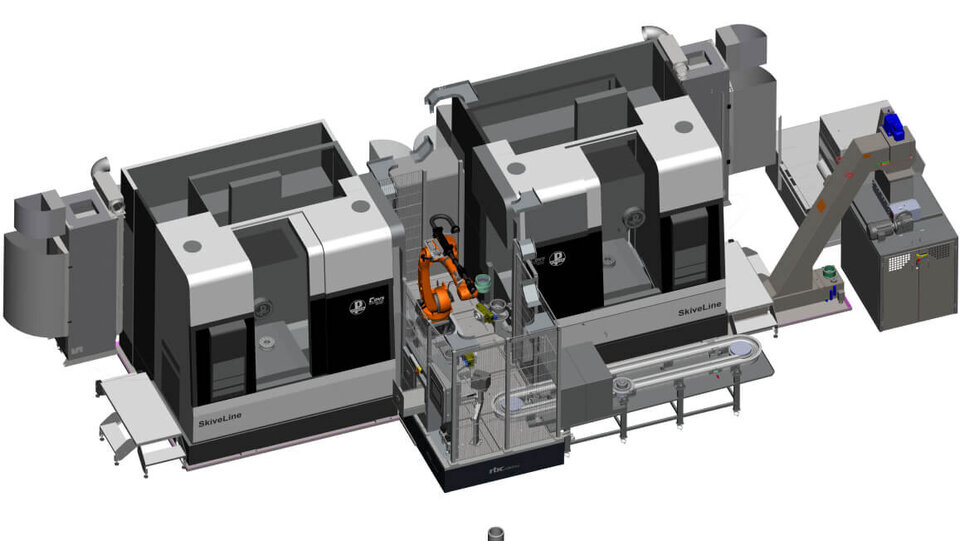

Frank Götz is Managing Director of rbc robotics, the automation experts of the DVS TECHNOLOGY GROUP. In context of In a Word, he shares his thoughts on 4 topics that are currently of particular concern to the automation sector.

Lack of skilled workers and the role of automation

Automation is becoming increasingly indispensable in view of the growing shortage of personnel. The demand for highly qualified workers is constantly increasing. Automation technologies enable companies to automate manual activities in order to compensate for the need for personnel. This not only helps to ensure production continuity, but also relieves skilled workers of repetitive tasks, freeing up their capacities for more complex and innovative tasks. In summary, automation is a key to coping with demographic change and ensuring the competitiveness of companies.

Cobots: the future of manufacturing

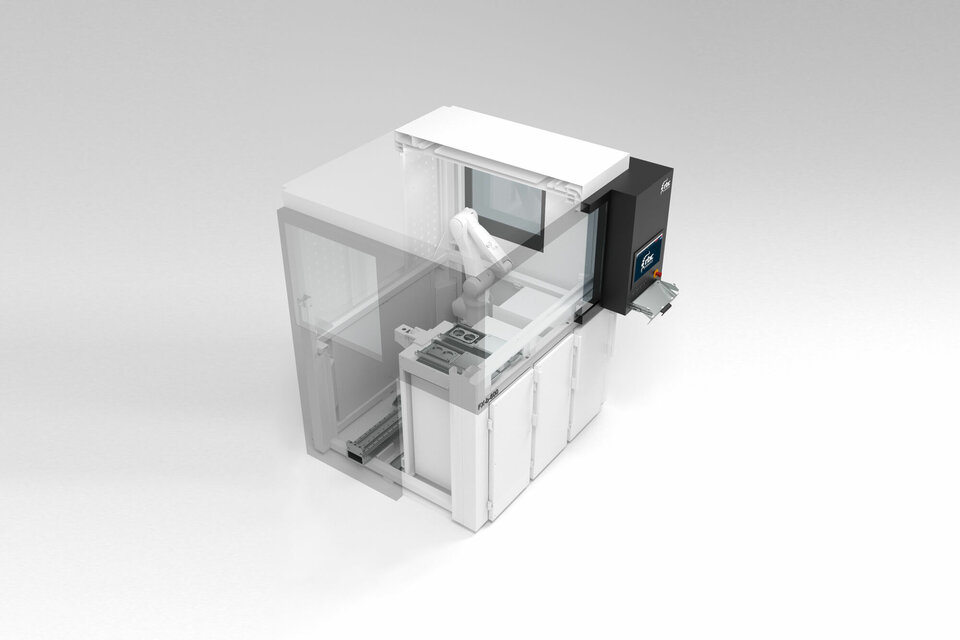

The introduction of collaborative robots, also known as "cobots", which work side-by-side with employees, will further revolutionize the manufacturing industry. Cobots are designed to work safely in a shared movement space with humans, making collaboration and information sharing much easier. They currently only perform simple, monotonous tasks, thus reducing the workload on employees.

This "human-robot" relationship increases productivity and creates a shared working environment.

Common EU-wide standards for the legally compliant marketing of such systems and the increasing acceptance in industry, trade and society will immensely increase the presence of "cobots" in many new areas.

We at rbc robotics have been active in the field of cobots since 2015. First as a Universal Robots partner, later with our partners ABB and KUKA. We still see enormous growth potential in this area and will continue to drive it forward.

The role of automation for more sustainable production

Robotic automation plays a crucial role in the implementation of sustainability and environmentally friendly development. Numerous environmental, social and economic benefits can be realized through the use of robots in various industries.

A significant contribution to sustainability lies in increasing the efficiency of production processes through robot automation. Robots can perform monotonous and time-consuming tasks with high precision and speed, which not only increases productivity but also reduces the consumption of resources. In addition, modern industrial robots are becoming increasingly energy-efficient thanks to the latest technologies, such as energy recovery.

An additional aspect is the improvement of occupational health and safety for employees. Robots take on dangerous and unhealthy tasks, reducing the risk of accidents at work and long-term damage to the health of human workers.

Another key point is the durability of robot systems. High-quality industrial robots achieve a technical availability of > 99% and are designed for a service life of over 50,000 operating hours. Systems that have been operating reliably for more than 15 years are not uncommon among our customers.

AI in automation

We have been using AI-based camera systems to detect components or for quality assurance for some time now. It is impressive how powerful the systems already are. Even with just a small amount of reference information, reliable decisions can already be made.

But despite all the euphoria, we have also found that our employees ultimately make a decisive contribution to success by training the systems accordingly. In other words, without the expertise and experience of our employees, it is not possible and this encourages us to continue investing in the training and development of our employees.

Ultimately, we see AI in our field of activity as a tool for optimizing and automating activities such as the evaluation of large volumes of data.

What do you think?

We are looking forward to your opinion.

Send us an e-mail and let’s talk:

communication@dvs-technology.com