The latest machine generation from the world market leader in honing

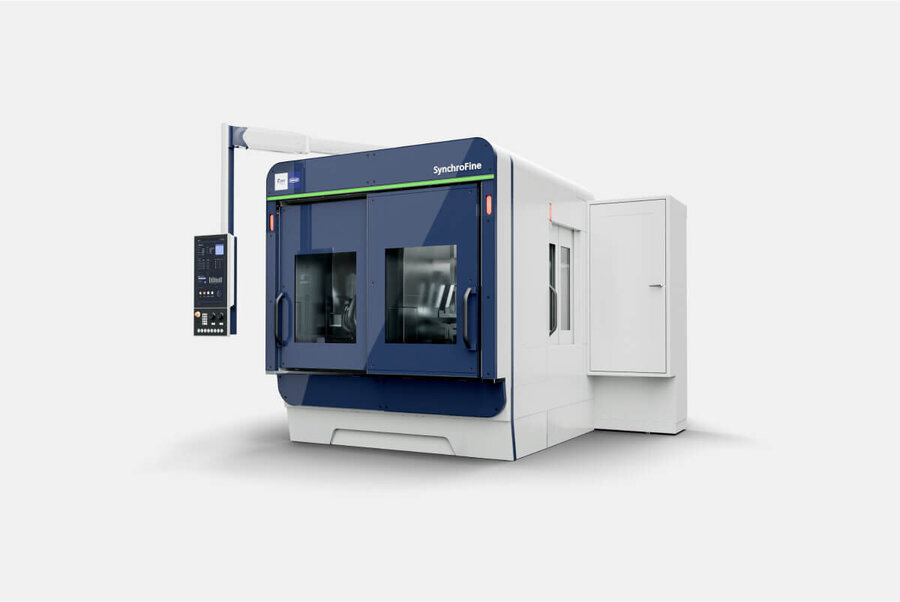

PRÄWEMA Antriebstechnik, world market leader in gear honing will present the latest machine generation for geared drive components at EMO 2023 and Motion+Power 2023: The SynchroFormV Advanced for efficient complete machining around the gearing of rings and shaft components and the SynchroFine, the compact CNC machine especially for gear honing of rings and shaft components.

At EMO 2023, Präwema Antriebstechnik will present the latest generation of the SynchroFormV Advanced. The system is specially designed for producing geared drive components. At EMO, visitors can experience the manufacturing of typical components for an electric drive train up close and personal. The machine is a further advancement of the SynchroFormV. The automation has been completely redesigned. Moreover, the new machine’s plug-and-play capability makes it easy to reconfigure it from a jump rail machine to a full-fledged, highly efficient double-spindle machine.

Available in single or multi-spindle versions, the machine from the DVS TECHNOLOGY GROUP subsidiary offers optimized solutions for the soft and hard fine machining of geared components, such as stepped planetary parts, with its range of technologies. Efficient cycle times and high-precision processing results make it easier to manufacture geared drive components with diameters up to 150 mm in small or large series. The gearing range of the machine is between module 0.3 and module 3.5. Additionally, SynchroFormV Advanced can be efficiently expanded with core skiving technology for lathing and deburring.

Would you like to learn more about SynchroFormV Advanced? Are you looking for other product or technology solutions for gear cutting? The best thing to do is to contact the experts at PRÄWEMA Antriebstechnik directly and without obligation.

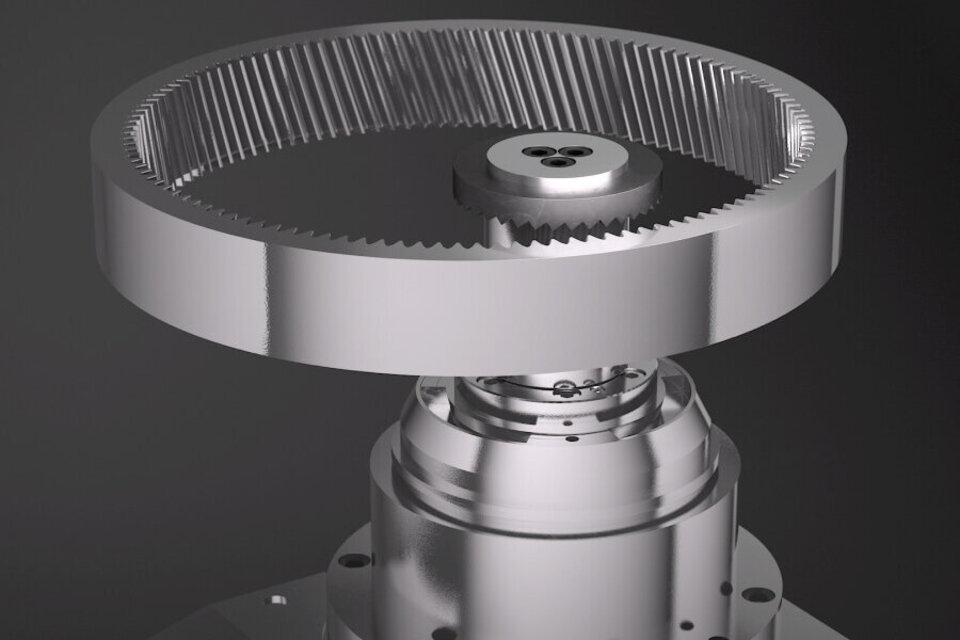

Präwema’s second highlight at EMO will be the SynchroFine honing machine. Honing of the external gears allows significant optimization of the surface quality. Präwema is the market leader in this processing technology. With material removal of about 50 µm per flank, a reliable process achieves appropriately high gearing quality, allowing stringent requirements for noise prevention to be met.

SynchroFine is especially unbeatable for hard machining of gears on disk- and shaft-shaped workpieces, because the machine and technology can be optimally combined. Its machine bed is made of natural granite for geometric precision and stiffness. Combined with DVS TECHNOLOGY GROUP’s tool solutions, this makes for a powerful unit.

Another highlight at EMO 2023 is a new, highly efficient deburring process that allows defined edge breaks of the tooth flank economically and in seconds, thus expanding the technology range: VarioChamfer.

Would you like to learn more about the SynchroFine, the world's leading honing machine for toothed components? The experts at PRÄWEMA Antriebstechnik are at your disposal.