One Group, one drive, one design

At EMO 2023 we presented our machines and further developed manufacturing solutions in turning, gear cutting and grinding in new splendor. Be inspired by our trade show video and learn more about the first 5 beauties.

The new design stands for a clear visual structure with a generous pane area, exciting proportions, dynamic fronts, ergonomic touch-screen control panel, support arm system, ergonomic foot area and generous working space. In addition, however, it should not be forgotten that each of the five machines presented is already a highlight on account of its inner values alone.

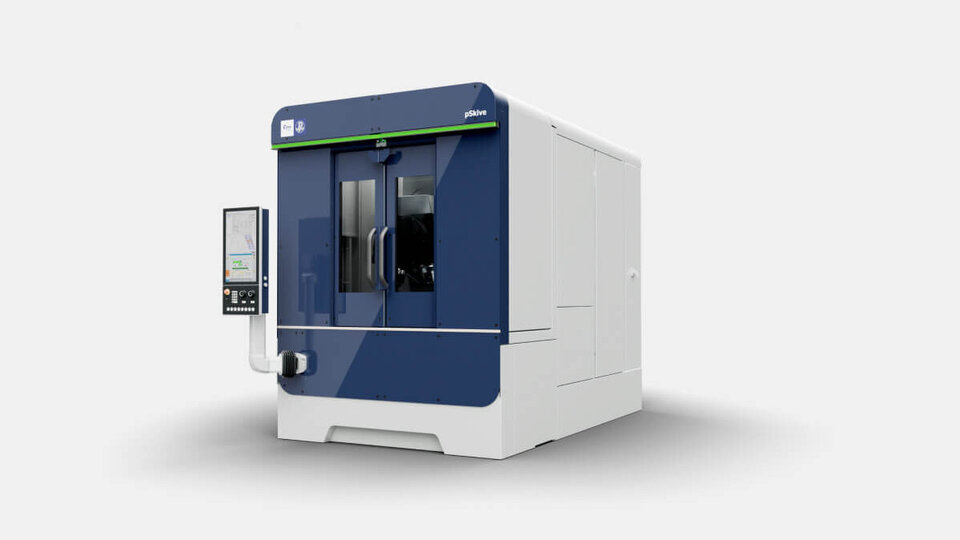

pSkive

The pSkive is a new machine developed by Pittler T & S for hob peeling. It will be presented to a large trade audience for the first time at EMO 2023. It sets new standards in gear machining and is ideal for the production of high-quality gear parts in medium and large quantities. Based on Pittler's advanced and proven Skiving Technology, the pSkive produces high-quality internal and external gears efficiently and precisely. The machine's gear cutting range is between module 0.3 to module 5 and processes workpieces up to 315 millimeters in diameter.

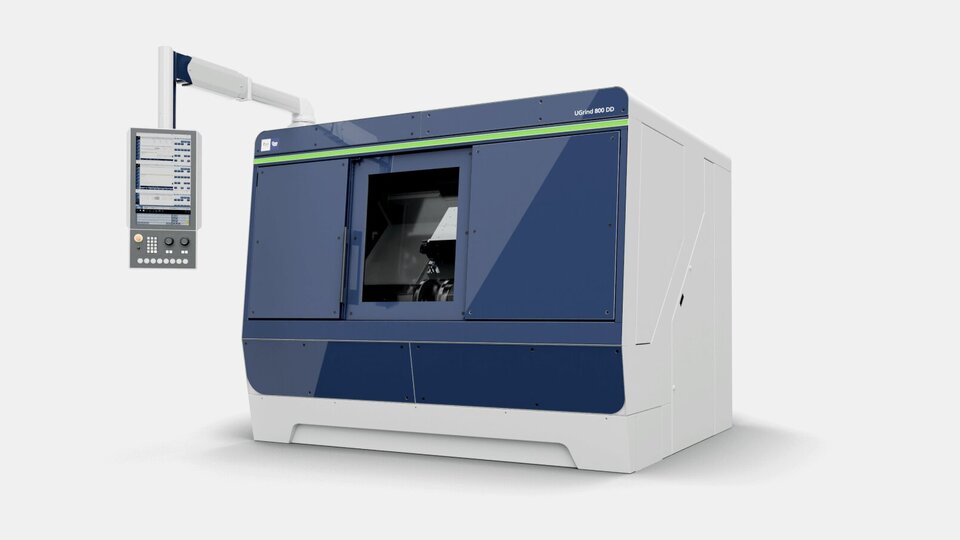

UGrind 800DD

Especially for the efficient and precise machining of brake discs, DVS Universal Grinding has developed a new machine with two opposing powerful grinding spindles based on the UGrind already established in the market: the UGrind DD. This allows simultaneous machining of brake discs on both sides and relies here on the so-called double surface grinding process. An in-process measurement ensures the dimensional accuracy of the workpiece. Before machining, the system determines the position in the Z-direction and the friction ring thickness. With this data, the brake disc can be ground to size on both sides. This ensures compliance with the tight manufacturing tolerances even with a short machining time.

The UGrind DD from DVS Universal Grinding. Specially designed for double-sided machining of coated brake discs

The UGrind DD from DVS Universal Grinding. Specially designed for double-sided machining of coated brake discs

235 VM

The new hard machining center from the 235V series from Buderus Schleiftechnik: the 235VM, which was primarily designed for manufacturers of electric drives. Areas of application are shaft-shaped components with high form and position requirements as well as low tolerance specifications, such as rotor, input, intermediate and drive shafts of electric drives. After testing, however, other types of workpieces are also possible. Thanks to the consistent use of the modular principle, the machine can be tailored specifically to the application or the range of components.

The 235V machine series from BUDERUS Schleiftechnik. The centre drive variant 235VM is primarily used for the complete finishing of rotationally symmetrical, shaft-shaped workpieces.

The 235V machine series from BUDERUS Schleiftechnik. The centre drive variant 235VM is primarily used for the complete finishing of rotationally symmetrical, shaft-shaped workpieces.

SynchroFormV Advance

The SynchroFormV Advanced is a further development of the previous SynchroFormV with a revised automation concept. In addition, the new machine can be easily reconfigured from a jump-slide machine to a fully-fledged and highly efficient double-spindle machine via 'plug-and-play'. Economical cycle times as well as high-precision machining results facilitate the production of toothed drive components with diameters of up to 150 millimeters in series and large-scale production. The machine's gear cutting range is between module 0.3 and module 3.5. In addition, with the SynchroFormV Advanced the core technology of skiving can be efficiently supplemented with turning and deburring operations.

The Präwema SynchroFormV is the efficient machine for complete machining around the gearing of drive components

The Präwema SynchroFormV is the efficient machine for complete machining around the gearing of drive components

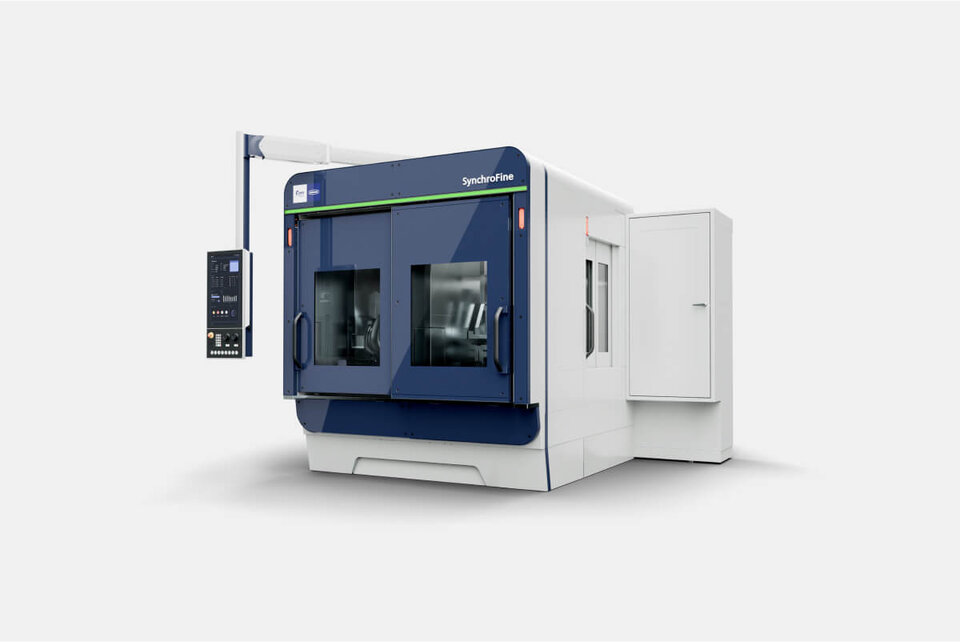

SynchroFine

Honing enables a significant optimization of the surface quality. Präwema is the market leader for this machining technique. With a material removal of about 50 μm per flank, a correspondingly high gear quality is achieved in a process-safe procedure, which means that the high requirements for avoiding acoustic conspicuities can be met. The SynchroFine is unbeatable, especially for the hard machining of gears on disk- and shaft-shaped workpieces, as it combines machine and technology in an optimal way. For example, its machine bed made of natural granite ensures maximum geometric accuracy and rigidity. In combination with the tool solutions of the DVS TECHNOLOGY GROUP, this creates a powerful unit.

The new design stands for a clear visual structure with generous pane area, exciting proportions, dynamic fronts, ergonomic touch-screen control panel, support arm system, ergonomic foot area and generous working space.

Can't get enough? Then watch our trade show video and be enchanted by our five beauties!