Paperless Spindle Production and Repair by WMZ Motorspindeln

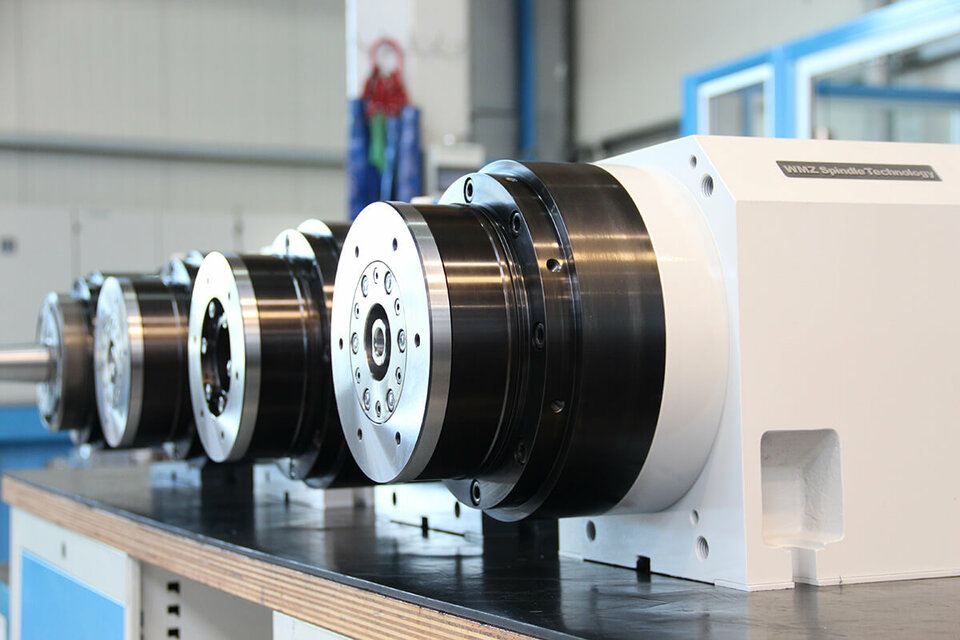

The motor spindles from WMZ, a subsidiary of the DVS TECHNOLOGY GROUP, are the centerpiece of the Group’s CNC machines. They make all the difference when it comes to the performance and cost effectiveness of a complete production. Knowing this, WMZ is placing extraordinary emphasis on the precision and robustness of its motor spindles, which are used in all of the Group’s machines. With the goal of achieving paperless spindle production and repairs, a small WMZ project team got together with the Ninox premium partner parcs in order to map the variety of spindle data in a cloud-based database.

The goal of this optimization is to improve quality control and clarify the technical requirements for customers and WMZ. The collection of all relevant data from production, maintenance, and repairs is one of the cornerstones for the qualitative design and further development of all products.

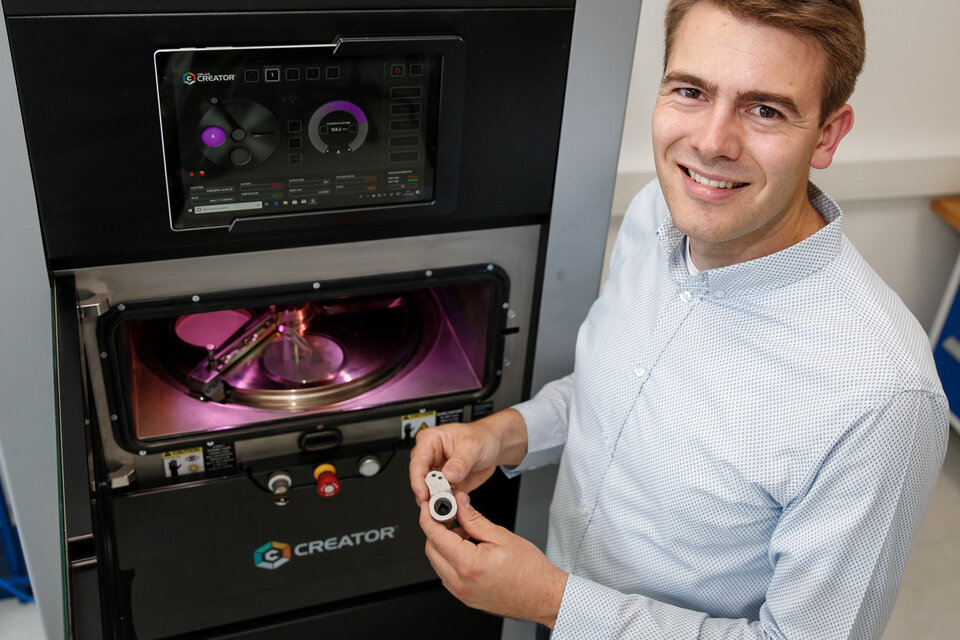

The extensive computational logic of the digital protocol and analysis tool is based on 25 years of analogue data in spindle construction. The technical implementation using the cloud-based Ninox platform is carried out by parcs.

Thanks to the digital project for paperless spindle production and with the help of parcs, WMZ was able to significantly optimize the production of its motor spindles, the processes related to maintenance and repair, its customer service, and its CO₂ footprint, resulting in clear advantages over the company’s competitors:

Positive effects on production of motor spindles

The assembly protocols are now available on tablets to more than 20 fitters in order to directly document and overview the work steps and test results. This enables the more efficient assembly of our milling, workpiece or grinding spindles and serves to establish a structured information database for future orders.

Positive effect on maintenance and repair

The system solution has also been expanded to include diagnostics during repairs. A digital documentation of the actual condition of each individual spindle is created, including photos and electronic reports, to enable all necessary repair work to be carried out in no time. This not only helps to more quickly and qualitatively figure out what steps to take, it also facilitates the identification and application of product correlations across large quantities.

Positive effects in service

The detailed analysis tools enable both the tracking of individual motor spindles throughout their entire product life cycle and the comparison of individual motor spindles and their performances with one another as well as cross-references. This speeds up the provision of services by WMZ and can be used for predictive maintenance in the future in order to train the service colleagues to take action before performance deteriorates – another potential benefit for WMZ customers and their production.

Positive effects for the climate

The advanced digital process saves 25 pages of paper per machined spindle. With an average number of over 200 spindles per month, this results in paper savings of over 60,000 pages per year.

Outlook

The next step will be the connection to WMZ's ERP systems (Enterprise Resource Planning) in order to also optimize the procurement of spare parts and shorten the internal communication channels. From this, WMZ is expecting optimized project management and customer-oriented order fulfillment due to the constant availability of materials.

The expansion to other product groups is also being planned and should take place over the course of the year.

Whether milling spindle, workpiece spindle, or grinding spindle: Our products can determine the performance and economic viability of a complete machine. That is why product robustness and precision are the top priority at WMZ. Find out more about the motor spindles from WMZ.

Conclusion

From an early stage, this project has proven to be quite a success for the entire team. It underlines the fact that WMZ can hold its own both organizationally and technologically, and that the company is fully committed to its products and the needs of its customers. Dr. Udo Tüllmann, Managing Director of WMZ, is overjoyed with the result: "In collaboration with our strong partner parcs, we have been able to turn this complex project into a solid, cloud-based IT solution in a very short time, which will improve our quality, efficiency, and service for the long term. We will continue down the same path with other product groups in order to optimally support our customers.”

Johannes Schmitz-Lenders, Managing Partner of parcs IT consulting, sees great potential for similar solutions in mechanical engineering and other manufacturing companies that need cost-effective individual solutions. He adds: "The combination of WMZ's expertise as a spindle manufacturer and our experience in the field of complex software systems have produced a tailor-made and modern solution. Using the Ninox low-code platform has significantly reduced development risks and costs.”

Find out more about parcs IT consulting and their expertise in requirements management, software development, low-code platforms, data analysis, and IT governance.