Perfect Interplay: Machine Tool + Grinding Wheel + Dresser

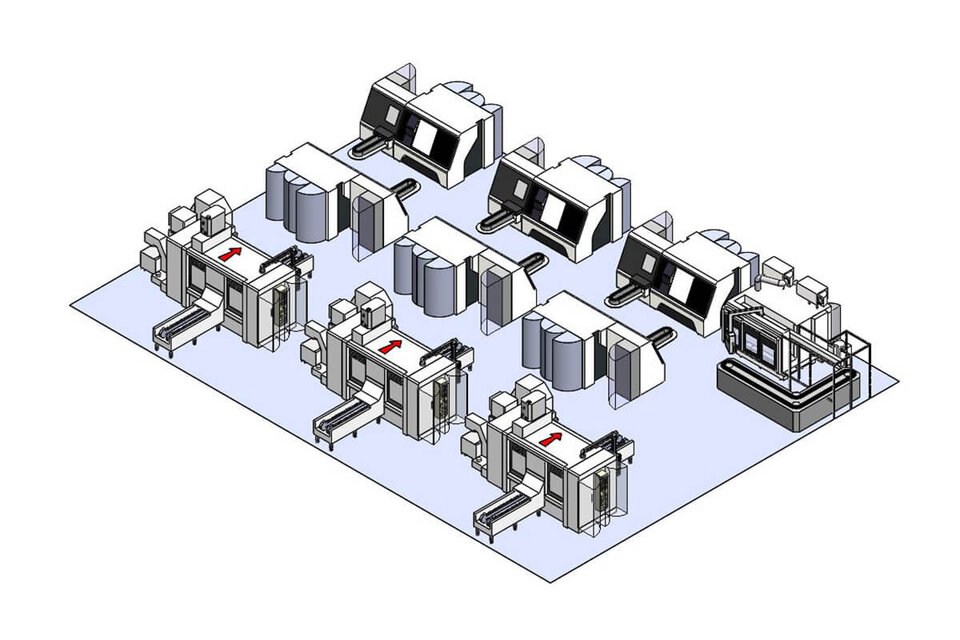

Mechanical engineering is not unlike the automotive industry. Automakers work very closely with tire manufacturers, because the car is only as good as the tire that transmits the force onto the road. The same interplay takes place within the DVS group of companies, where future-oriented grinding machines are equipped with perfectly matched grinding wheels and dressing rolls, which together form a turnkey system solution that ensures optimal machine performance and paves the way for the future of mobility.

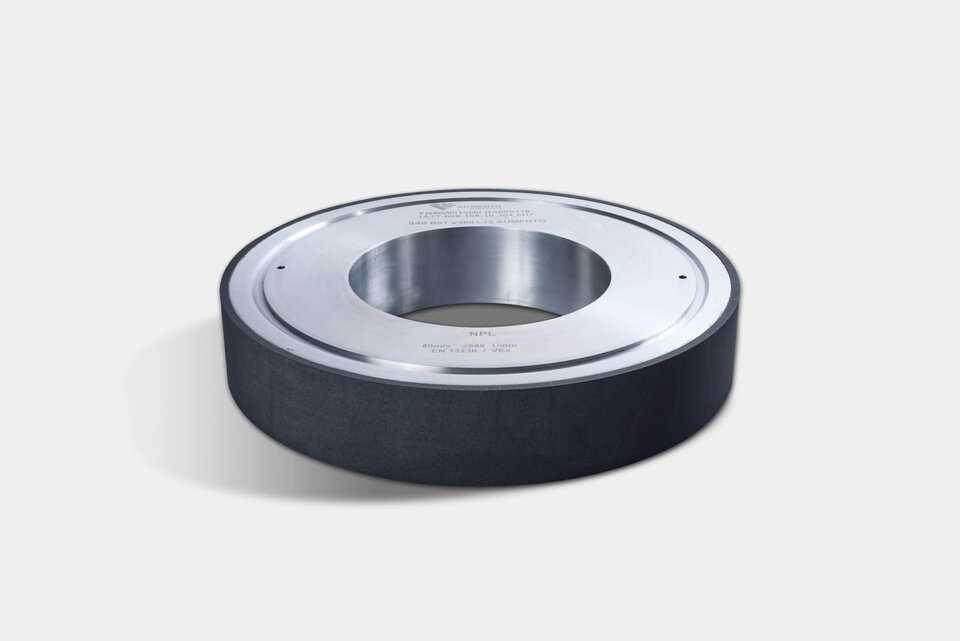

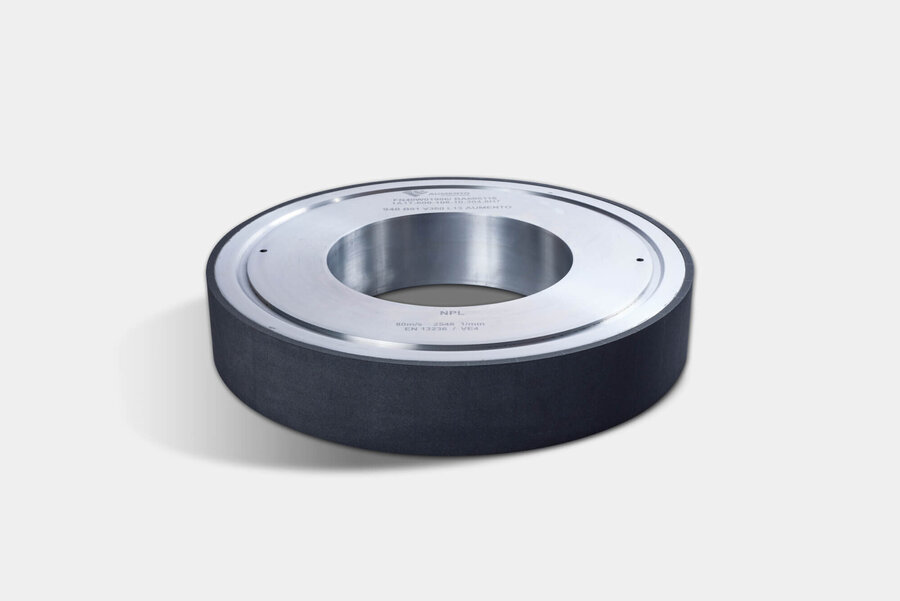

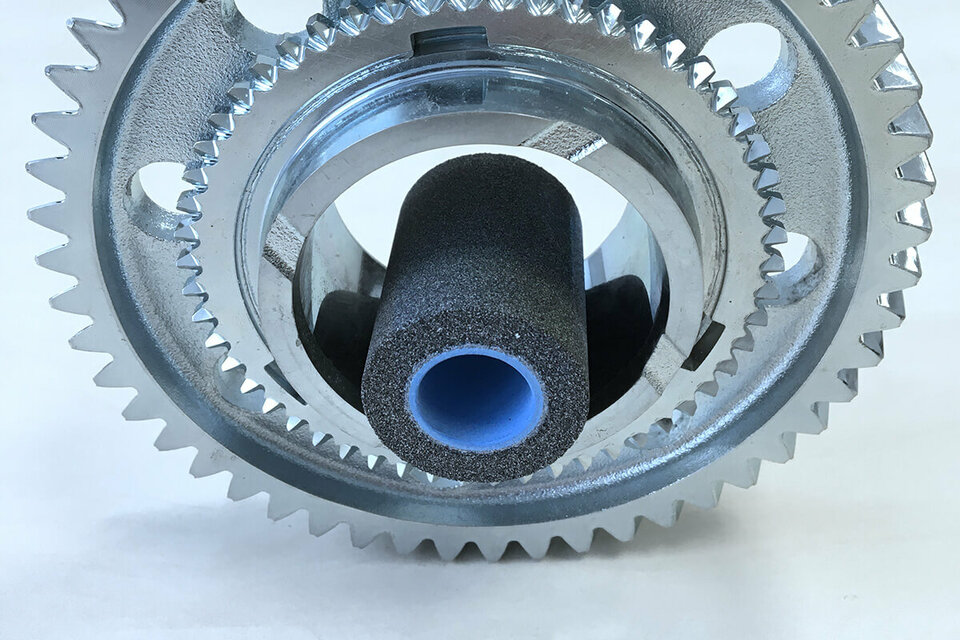

DVS subsidiary NAXOS DISKUS has developed ceramic-bonded CBN grinding wheels for the iCompact grinding machine from BUDERUS Schleiftechnik that are specifically matched to the machine and the required grinding process, and which shorten the dressing and profiling phases of the iCompact. This significantly improves the precision and economic viability of the machine tool. It also enables the processing of difficult-to-machine materials with a very high hardness far above 60 HRC. The grinding wheels reduce the machine's setup time considerably and increase productivity.

CBN and its benefits

CBN, which is an acronym for Cubic Boron Nitride, is a game changer for the internal grinding of, e.g., electric rotor shafts. NAXOS DISKUS has been offering CBN grinding wheels for grinding bores for many years. Compared to corundum and silicon carbide, CBN is harder and significantly increases the tool life. Together with diamonds, CBN is one of the super-hard abrasives.

NAXOS DISKUS offers different wheel variants that are used with the new abrasive grain generations for internal grinding. CBN grinding wheels are suitable for grinding materials that can no longer be machined economically with conventional abrasives, such as silicon carbide or corundum.

NAXOS DISKUS tailors the specification of its grinding tools to the different applications and thus offers the right grinding tool for every application. Find out more about the abrasive products from NAXOS DISKUS.

The technology was first used by the DVS TECHNOLOGY GROUP. “We see a bright future for CBN in the automotive sector, especially in the e-mobility segment. But also with the manufacturers of industrial gears,” explains Mario Arnold, Managing Director of NAXOS DISKUS.

The electric motor market in particular demands the use of extreme surface qualities for gears and shafts – among other things for noise reduction. This can only be achieved with high-quality internal grinding tools.

Whether for automotive or hydraulic components, injection nozzles for combustion engines, details made of technical ceramics, or for HVOF*-coated parts: Ceramic bonded CBN and diamond grinding wheels from NAXOS DISKUS are the perfect solution for highly efficient production of diverse users.

* HVOF – high velocity oxygen fuel spraying, is a thermal coating process used to finish surfaces.

Finding the right dressing and grinding tool can be a complex process that depends on the situation. The application engineers at NAXOS DISKUS are always available to our customers to find a suitable solution and to provide ongoing support.

“Our customers are very pleased with the results we’ve achieved,” reports Mr. Arnold. This is where high process stability meets greater cutting performance.”

One Group, one standard

Diamond dressing rolls have different diamond designs. Both natural diamonds and industrial diamonds are processed, with the proportion of industrial diamonds increasing. The materials used are MKD, CVD, and PCD. Their defined shape ensures constant and reproducible quality over the entire service life.

Since CNC-controlled dressing processes have been introduced, many different CBN and diamond form dressing rolls have been released on the market, which can make it difficult or downright impossible to pick and choose yourself.

NAXOS DISKUS not only supports customers in choosing the right product, the company also works closely with sister companies DVS Tooling and BUDERUS Schleiftechnik in order to reduce the variety to a manageable level for more sensible warehousing and cost-effective tool production. The companies of the DVS TECHNOLOGY GROUP contribute to the economical optimization of the grinding processes of every user.